HEAVY LIFT & PROJECT CARGO:

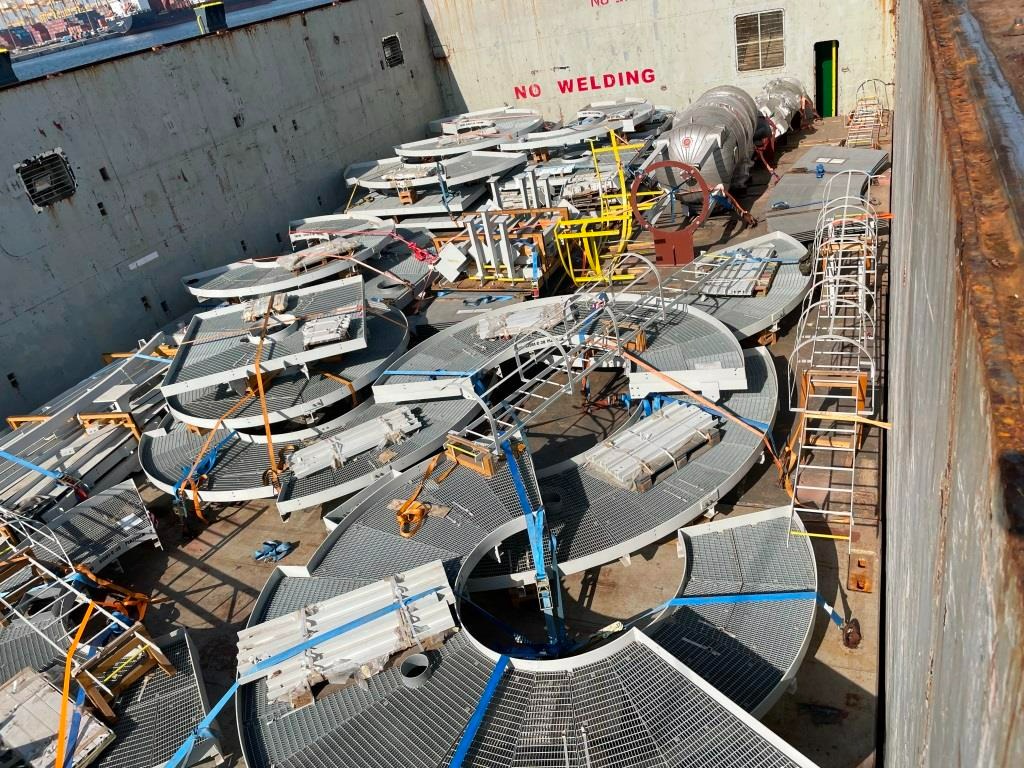

We have significant expertise in advising on a diverse array of heavy lift and project cargoes. Our experience covers everything from reactors and pressure vessels for refineries and petrochemical plants to components for power generation and distribution, including boilers, turbines, generators, and transformers. We also handle break bulk cargo (such as boxes, crates, unpackaged units, and skid-mounted equipment), rolling stock (including locomotives, railway equipment, bulldozers, and cranes), and floating equipment like dredgers, barges, and yachts.

Given that each cargo is unique in its nature and composition, meticulous planning and coordination are essential to ensure successful handling and transportation.

Our comprehensive services include:

- Inspecting cargo at loading and discharge locations

- Advising on and supervising stowage and sea-fastening procedures

- Issuing certificates and warranties

- Calculating forces and determining the necessary lashings

- Performing strength calculations for international transport (e.g., for cranes and large structures)

- Providing route analysis and advice, including weather and sea state forecasts

- Approving towage operations

MARINE WARRENTY SURVEY (MWS):

A Marine Warranty Surveyor (MWS) is appointed primarily to safeguard the interests of the underwriter rather than to act as a marine consultant. Their main responsibility is to ensure that marine operations are conducted in a way that minimizes the risk of damage to property, human life, and the environment. Although all marine operations inherently carry some degree of risk, the goal is to keep these risks “As Low as Reasonably Practicable” (ALARP).

To fulfill their duties effectively, the MWS must ensure that only those operations which do not pose a significant risk are approved. However, it’s important to note that marine warranty companies are not contractually bound to any of the contractors involved in the operation, such as tug operators, shipyards, installation contractors, riggers, or designers. Therefore, the MWS cannot issue direct instructions to these parties.

While an experienced surveyor ultimately has the authority to issue the Certificate of Approval (COA) and is present during the actual marine operations, the role of the Marine Warranty Surveyor encompasses several key elements:

1.Review Engineering Documents and Calculations: The surveyor examines all relevant engineering documents and calculations to ensure they are accurate and meet required standards.

- Verify Equipment and Related Certificates: The surveyor checks that all equipment used in the marine operations is properly certified and in good condition.

- Review Marine Operation Procedures: The surveyor evaluates the procedures for the marine operations to confirm that they are safe and effective.

- Attend Marine Operations: The surveyor is present during the operations to monitor the execution and ensure compliance with approved procedures and safety measures.

- Prepare a Report: After the operations, the surveyor compiles a detailed report outlining their findings, any issues observed, and overall compliance with the marine warranty requirements.

These steps ensure that marine operations are conducted with a focus on minimizing risks and adhering to safety and regulatory standards.

Protection and Indemnity (P&I) Insurance

Overview:

P&I insurance is a mutual insurance system designed to cover the liabilities that shipowners encounter in their operations. This insurance is vital for safeguarding against various risks, including third-party damage, environmental pollution, and crew-related claims.

Key Features:

- Liability Coverage:

P&I insurance provides coverage for a broad range of liabilities, such as:- Damage to cargo

- Injuries to crew members and passengers

- Environmental pollution

- Collisions with other vessels

- Mutual Associations:

Most P&I insurers function as mutual associations, where shipowners serve both as the insured and the insurers. Members contribute to a shared fund that is used to settle claims. - Limits of Liability:

P&I clubs often establish limits on coverage for specific claims, though certain liabilities, like those arising from collisions, may have higher or even unlimited coverage. - Risk Management:

P&I clubs also offer risk management guidance and support, helping shipowners reduce their exposure to claims through best practices and training. - Regulatory Compliance:

Numerous maritime regulations mandate that shipowners obtain P&I insurance as a prerequisite for operating vessels, ensuring they can cover potential liabilities linked to their activities.

Importance in the Maritime Industry:

P&I insurance is crucial for maintaining financial stability and regulatory compliance within the maritime sector. By protecting against significant liabilities, it allows shipowners to operate with greater assurance, knowing they are shielded from unexpected events.

Challenges and Considerations:

- Evolving Risks:

As maritime operations become increasingly complex and regulations tighten, P&I clubs face new challenges, including emerging liabilities related to cyber risks and environmental regulations. - Cost Management:

The cost of P&I insurance can vary based on the industry’s claims history, requiring shipowners to engage in careful financial planning.

Conclusion

P&I insurance is fundamental to the maritime industry, offering essential protection for shipowners against a wide array of liabilities. As the sector evolves, P&I clubs must adapt to new challenges while continuing to provide effective risk management and coverage solutions to their members.

HOLD / HATCH INSPECTION:

Hold Inspections

FIVEOCEAN inspectors ensure that the ship’s hold is fully prepared to accept your cargo. Our hold inspections evaluate several factors that could impact your cargo’s quality. Our qualified and experienced inspectors:

- Confirm that the hold is free from rust or paint chips that could potentially damage or discolor your cargo.

- Ensure that no remnants from previous cargo are left behind, including in hard-to-reach areas.

- Check for any wooden partitions or dunnage that might interact with your cargo and create a fire hazard.

- Review the ship’s log to identify any previous cargo that could pose a risk to your shipment.

- Pay particular attention to residues from previous cargo, such as seeds or grains, which may trigger quarantine issues.

- Inspect for any signs of moisture or previous water damage in the hold or bilge.

Hatch Inspections

Defective hatch cover seals and securing methods are common causes of cargo damage and rejection. FIVEOCEAN’s hatch inspections ensure that hatch covers are in good condition and do not endanger your cargo. Our inspectors:

- Visually check hatch covers at departure and arrival to verify water tightness and proper function.

- Look for any visible damage, holes, or leaks that could compromise cargo quality.

- Perform Chalk, Hose, and Ultrasonic Leak Detection (ULD) tests to provide an objective assessment and verification.

FIVEOCEAN offers thorough, independent hatch and hold inspections as part of our commercial carrier inspection services, ensuring trusted bulk cargo management.

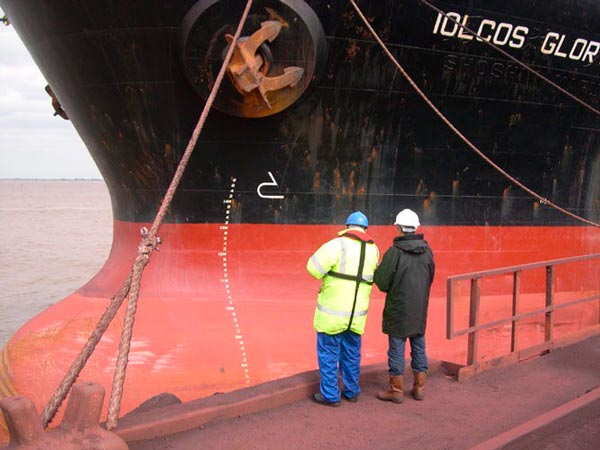

DRAFT SURVEY:

Draft surveys are analytical processes that use the measurement of a vessel’s draft to estimate its weight under different loading conditions. These surveys depend on draft readings, which can be obtained from the vessel’s stability manual or from physical marks on the hull.

These surveys are necessary because traditional methods for calculating the weight of large vessels, like container ships and carriers, are impractical. Moreover, companies need a swift method to gauge the weight of cargo being loaded without measuring each item individually. Draft surveys offer an effective solution, helping to save time and reduce costs.

H&M SURVEY:

A Hull and Machinery Survey serves to evaluate the nature, cause, and extent of damage, and also assists ship owners and underwriters by providing repair specifications and facilitating tender procedures.

Typical causes of hull and machinery failures include collisions with other vessels or fixed and floating objects (FFO), grounding, machinery malfunctions, fires or explosions, and adverse weather conditions.

FIVEOCEAN surveyors are equipped to deliver detailed damage assessments, provide repair specifications, and offer supervision as required.

BUNKER SURVEY:

A bunker survey ensures that the ship is receiving the full amount of fuel or diesel as outlined in the nomination and the bunker delivery note (BDN). It provides documented proof of the actual quantities of fuel oil and diesel oil delivered and can be used to resolve any claims or disputes over discrepancies.

The Stages of a Bunkering Operation

Bunkering operations are split into three stages: preparation, performance, and wrap up.

Preparation

Preparation is a critical phase in the bunkering process, as it establishes the groundwork for efficient operations and helps prevent oil spills, which can negatively impact the environment and public health.

Key components of the preparation stage include:

- Equipment Inspection: Ensure all bunkering equipment, including hoses, pumps, and meters, is functioning correctly.

- Tank Inspection: Thoroughly check the ship’s storage tanks for integrity and suitability to receive marine fuels.

- Safety Measures: Inspect gangway handrails and ropes, secure vertical ladders, confirm adequate lighting, check for slippery conditions on ladders and gangways, and ensure that all personnel involved in the bunkering are well-rested and not showing signs of fatigue.

Performance

During the performance stage, fuel is transferred to the ship. Effective teamwork, precise control of equipment, and strict adherence to safety procedures are vital for a smooth and controlled transfer process.

Key activities during the performance stage include:

- Execution: Follow the bunkering plan, which outlines specific procedures for the vessel being serviced.

- Monitoring: Carefully supervise the process to address any issues that arise and maintain control over the operation.

Wrap Up

The wrap-up stage involves concluding the bunkering operation with a focus on safety and accuracy.

Key steps during the wrap-up stage include:

- Final Safety Check: Verify that all safety protocols were followed throughout the process.

- Verification: Ensure the vessel received the correct amount of fuel and that it meets the required quality standards.

- Documentation: Complete the operation with a detailed record of the process for regulatory compliance and future reference.

LASHING:

When FIVEOCEAN manages the stowage, lashing, and securing of heavy cargo units on deep-sea vessels, the surveyor’s role is to ensure these units are handled and loaded safely. This involves advising on effective stowage practices and verifying that the cargo is securely lashed and properly arranged for seaworthiness.

It is crucial to apply appropriate load-spreading techniques to avoid exceeding the maximum allowable loads on the ship’s tank top or hatch covers. During this process, you will be trained to calculate the correct number of lashings needed to prevent both transverse and longitudinal shifting of the cargo, as well as tipping. Additionally, you will supervise the choice and application of lashing materials to ensure they are used correctly.

CONTAINER INSPECTION:

Containers are promptly inspected for maintenance, repairs, and cargo loading supervision to ensure they adhere to International Organization for Standardization (ISO) guidelines for structural integrity. FIVEOCEAN conducts these inspections to verify that containers meet safety standards and are fit for long-distance transport. Containers must comply with regulatory requirements before goods can be loaded.

Manual inspections generally involve examining the container’s roof, doors, and floor for damage such as rust, wear, tears, leaks, broken hinges, or malfunctioning locks. The goal is to ensure safe and efficient cargo transport while minimizing the risk of damage due to container issues or security concerns.

LOADING / UNLOADING SUPERVISION:

Loading and discharge surveys are vital inspections performed during the loading or unloading of cargo from a vessel. They ensure that cargo is handled properly, verify the quantity of goods loaded or unloaded, and record the condition of both the cargo and the vessel.